Tipper Semi Trailer For Nigeria

This is the third time a Nigerian customer has cooperated with us. So far, he has purchased ten tipping semi trailers from us. According to his feedback, these ten vehicles are all running well. This time he wanted to help his friend buy a tipping semi trailer. His friend had just entered the industry and wanted to buy one for a try.

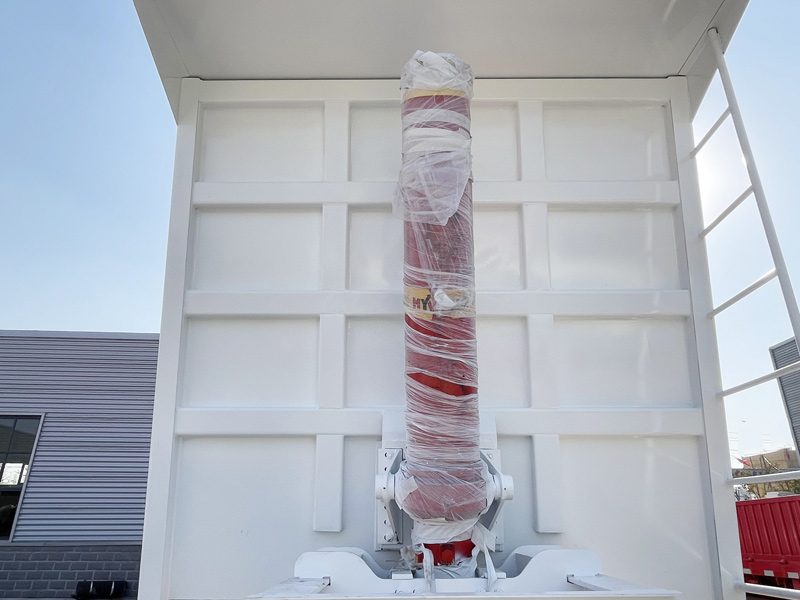

tipper semi trailer for sale near meThe current tipper semi trailers have upgraded to the latest paint technology: electrophoretic primer + powder spraying. The process is based on electrophoresis, through corona discharge, the topcoat powder is uniformly attached to the car body and then melted at high temperature to form the topcoat.

Its advantages just make up for the shortcomings of spray paint. It can form a standard 60~120μm topcoat thickness in a balanced manner. There will be no dead corners during spraying, no flow marks on the paint surface, and stronger adhesion than spray paint.

In terms of corrosion resistance, the powder spray paint surface has no change in salt spray resistance for 1000 hours and no change in resistance to humidity and heat for 500 hours. The salt spray should be free of bubbles and rust, 35 degrees Celsius 5% saltwater, no change after 400 hours of continuous spraying.

Details of Semi dumper trailer:

Tipper semi trailer inspection chart

The maintenance of dump semi trailers

- Maintenance of hydraulic system; maintenance of hydraulic system mainly starts with gear oil. For gear oils with high viscosity, it is forbidden to use different types of gear oils mutually or add gear oils that do not meet the requirements.

- Keep the impurities in the hydraulic oil filter element before changing the oil. Always keep the oil clean and replace it regularly. If there are impurities in the operation of the hydraulic transmission system, they will enter the valve and hydraulic cylinder along with the pipeline, causing the valve to jam or hydraulic damage. The seal in the cylinder will affect the use of the lifting system.

- The seals in the hydraulic transmission system should be checked for damage and aging before the winter, and should be replaced in time and checked regularly.

- Check the hydraulic pipelines and observe whether there is any looseness and oil leakage at the joints. If so, find out the reason and deal with it in time. In addition, observe whether the hose is cracked and replace it in time.

- The surface and refueling port of the fuel tank of a 40-ton dump trailer to prevent impurities from entering the fuel tank. Check whether the retarder is working properly and whether there is any hidden danger in the gear bite of the connecting rod.

- On the surface of the hydraulic cylinder, check whether there are scratches or scratches on the surface of the piston rod. If necessary, it should be replaced in time, otherwise the gear oil will leak out and affect the lifting process.